Target 1

Increasing the total wood yield of wood used in production in each plant to a minimum of 90% in 2025

Our wood yield, an important performance indicator - is steadily improving: In 2024, we achieved wood yields of 87% to 92% in our plants, depending on the plant (2020: 82% to 91%). Due to ongoing innovation in sorting and impurity recognition as well as concrete investments in such technologies, we consider a minimum share of 90% in each production plant feasible until 2025. Four factories that already have a yield of over 90%, our goal is to maintain it. The current technology does not allow a yield of 100%; especially the added recycled wood will always contain a share of undesirable content.

Wood yield: Our performance and target

| 2020 | 2021 | 2022 | 2023 | 2024 | Target 2025 | |

| Technical wood yield in per cent | ||||||

| Highest yielding plant | 91.1 | 91.3 | 91.8 | 91.1 | 91.7 | 90.0 |

| Lowest yielding plant | 81.8 | 83.4 | 82.5 | 84.3 | 86.9 | 90.0 |

Target 2

Increasing the share of post-consumer recycled wood from 40% (2020) to 50% (2025)

We use our strength as the largest user of recycled wood in Germany, to consistently improve the cascading use of wood. Thereby we contribute to a ‘circular economy’, whereby nothing is wasted – i.e. end-of-life wood products become valued raw materials rather than waste in landfill sites.

We want all wood products, including our own, to be repurposed. In practice, our cascading use system means that already today we use predominantly, with a share of 53.5%, post-consumer recycled wood.1 The second-largest share is comprised of sawmill residues, representing 25%. The remaining 21% is accounted for by thinnings and damaged wood, mainly from domestic forests. To ensure that our fresh wood and decorative paper are responsibly sourced, we only use raw materials from controlled sources. In addition, 90% of the wood resources we use for production stem from Germany, the remaining 10% from directly neighbouring countries.

1 As post-consumer material we consider prepared recycling wood from damaged pallets from packaging, used furniture or kitchens as well as internal rejects; the latter comprise only 2.5% of the total recycled wood.

Recycled wood: Our performance and target

| 2020 | 2021 | 2022 | 2023 | 2024 | Target 2025 | |

| Share of post-consumer recycled wood in our wood mix in per cent | 41.7 | 46.2 | 48.1 | 50.7 | 53.5 | 50.0 |

The volume of this material available to us is affected by reuse and recycling initiatives in the European Union, economic development, patterns of consumer behaviour and furniture retailers reclaiming used furniture. In addition, if we can help influence the behaviour of consumers and businesses, then we may see increased availability of post-consumer wood.

Whilst we want to obtain greater quantities of recycled wood, we also insist on using only the highest quality materials. Our boards are regularly tested in our central lab in Arnsberg, and we work with our suppliers to achieve 100% compliance with product quality rules.

For our high quality products, we use wood recycled according to the standards of the German Waste Wood Ordinance, which is the strictest in Europe, and is largely free of chemical, metallic or mineral impurities.

79% of the wood raw materials used in our products are sawmill residues and recycled wood.

Case study

Sorting, cleaning and testing recycled wood

Our yield rate is an expression of the quality of our main raw material: recycled wood. As the material comes into the plant we want to minimise all losses of material as we clean it. The very high yield rate achieved at our sites is down to our consistent investment in state-of-the- art technology. Our sorting and cleaning processes, supplier relationships, and rigorous testing are key to our success. The ‘sorting tower’ aims to ensure no unwanted materials, such as plastics, arise in our production lines. Indeed, we are pushing the boundaries of yield maximisation: the high number of sorting processes in our towers means increasingly finer fractions of raw material become available to us. In effect, we are reducing our reliance on fresh wood by-products by using recycled wood fibres as many times as possible.

Target 3

Manufacturing 10% of wood-based materials using biogenic binder content by 2025

In our production, we can process around 250,000 tonnes of resins, binders, additives and lacquers per year. To partially replace these with renewable raw materials, we are pursuing a concrete goal: by 2025, we aim to produce 10% of our wood-based products (measured by volume) using a share of biogenic resins. We also offer OrganicBoard Pure, a version with 100% renewable binder.

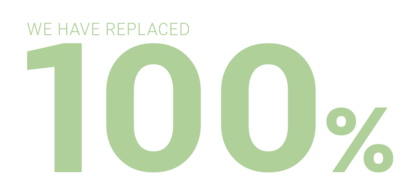

... OF FOSSIL GLUES WITH RENEWABLE ORGANICGLUE IN THE ORGANICBOARD PURE PRODUCT. A PARTICLE BOARD WITH 100% RENEWABLE BINDER AND 100% RECYCLED FIBRE.

Target 4

Develop specific indicators to assess water consumption and waste generation in accordance with GRI

As a waste management operation, we aim to minimise waste by recycling waste wood both materially and thermally. Despite our commitment and approach to recycling wood, other waste accumulates in the form of ash, waste wood residues and packaging.

Managing unavoidable waste

The Pfleiderer sites do not operate landfills. The combined heat and power plants in Neumarkt, Gütersloh and Baruth, as well as Heller Holz GmbH, are certified as waste management facilities. They thus fully comply with extensive waste management requirements. As a member of the German Federal Association for Secondary Raw Materials and Waste Disposal (Bundesverband Sekundärrohstoffe und Entsorgung e.V.), Pfleiderer plays an active role in promoting the advancement of cascading use in legal regulations, e.g. the German Waste Wood Ordinance.

The system features an automatic accounting module for categorising waste diverted from disposal, including preparation for reuse, recycling and other recovery operations for both hazardous and non-hazardous waste. Furthermore, the system will also include automated accounting of waste diverted to disposal including incineration (with and without energy recovery), landfilling and other disposal operations of both hazardous and non-hazardous waste.

WATER

As a result of the re-validation of our materiality assessment, we reprioritised the topic of water with regard to our impact. Despite most of our operating sites being located in water-rich regions, we acknowledge that water scarcity is a global problem, increasingly aggravated by the climate crisis. Consequently, how we manage water resources is also becoming strategically more important.

WATER MANAGEMENT

We are committed to using water resources responsibly and are on our way to transparently documenting our water needs. Transparent documentation is a prerequisite for adapting our water management to the expected changes in water availability due to climate change.

Target 5

Create a biodiversity management plan by 2025 for all production sites in or adjacent to areas with a nature protection status

Biodiversity is a strategically important topic for our company. We evaluated our impact on biodiversity using a biodiversity checkfor companies provided by the public platform “Unternehmen Biologische Vielfalt” (UBi). The results indicate that our company has a major impact on biodiversity and therefore also has great potential to implement improvement measures. The evaluation is ongoing and suitable indicators are still to be established.

Target 6

Identify and mitigate potentially negative impacts on biodiversity in our wood supply chain by 2025

Although fresh wood in the form of thinnings and damaged wood only accounts for about 20% of our wood volume, we have started supporting one of our largest fresh wood suppliers in a concrete renaturation project. The supplier – a large public forest landowner – replaced spruce monoculture with a wetland landscape and site-adapted, resilient mixed-species forests. This project is continuing as a pilot, and additional projects are being discussed with other fresh wood suppliers.

In 2023, we have joined the "Biodiversity in Good Company" Initiative to advocate for the protection and sustainable use of biodiversity in partnership with other companies as well as political and societal stakeholders. The Initiative members are small-, medium-, and large-scale companies from Germany and other countries and a variety of sectors. They have committed themselves to including the protection of biological diversity into their sustainability strategies and environmental management by signing the Initiative’s Mission Statement and Leadership Commitment.

Target 7

Document 80% of suppliers to have signed our Code of Conduct for Suppliers by 2025

We are committed to systematically assessing the sustainability of our suppliers as part of our efforts to build a responsible supply chain. To this end, we have achieved our goal of introducing a framework for assessing the sustainability of our suppliers in 2023. This framework will enable us to better systematise our approach and report transparently on our supply chain sustainability improvements. We will continue to gather supplier data as part of our annual supplier assessments to give an indication of the maturity level in managing sustainability.

As a first measurable target, we aim to reach 80% of suppliers having signed our Code of Conduct for Suppliers by 2025 and 95% by 2030. In subsequent years, we will use the system to monitor and report on additional KPIs reflecting supplier sustainability. Suitable would be a standardised supplier rating such as EcoVadis as a prerequisite for future preferred supplier relations.

Read more about sustainability at Pfleiderer

These topics may also be of interest to you: