We are proud to be a naturally sustainable business

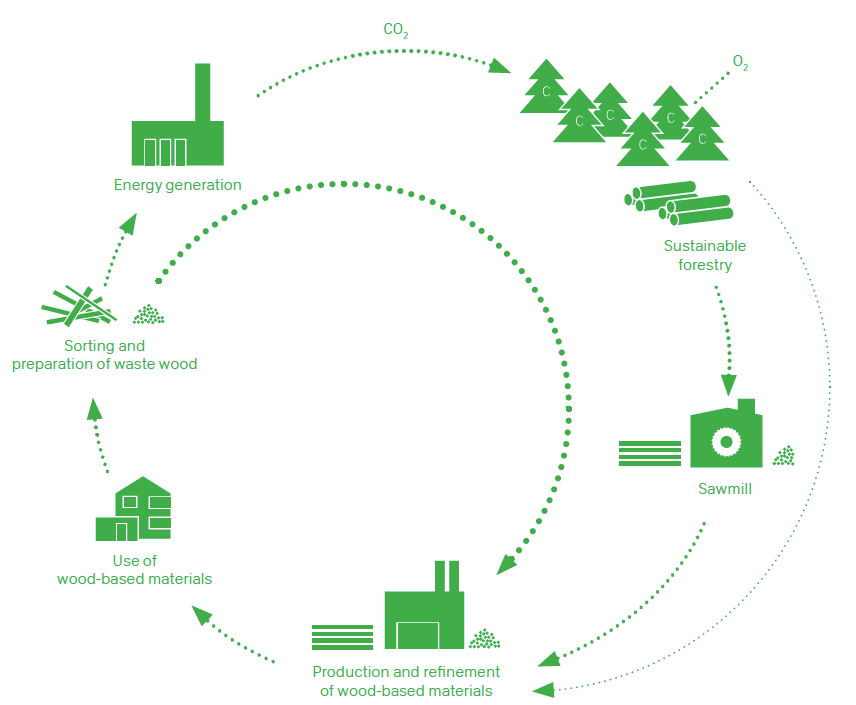

We use recycled wood, often several times, to create premium engineered wood panels. Our circular model demonstrates how carbon dioxide stored in wood is locked in after harvesting for the entire service life. It also ensures that we create maximum value, while having minimal impact on the planet.

We deploy modern techniques and technology to extend the lifecycle of our raw materials, working closely with our partners across the value chain to drive recycling rates up, and carbon emissions down. Of course, we understand that true sustainability means we must listen to our stakeholders, always act responsibly, and cultivate a safe, healthy work environment where our people can thrive.

PROFESSIONAL AND TRANSPARENT: WE WORK FOR OUR VISION

In 2022, we conducted a materiality analysis to comprehensively examine the impact of our business activities on the environment, the economy, and society. This was done in the three existing areas of action: materials, climate, and people. In 2023, we revalidated the topics and further expanded our objectives. With a view to the Corporate Sustainability Reporting Directive (CSRD), we conducted our materiality analysis again in 2024 in accordance with its requirements, involving internal and external stakeholders. Based on this, we have set ourselves goals.

Our Focus Areas

Our three focus areas are closely aligned with our commercial strategy, and are a central part of the commitments made in our Sustainability-Linked Financing Framework.

Materials

PRINCIPLES

- Circular economy

- Renewable resources

- Responsible procurement

- Protecting biodiversity

COMMITMENTS

- Maintaining our commitment to the circular economy through consistent recycling of wood-based materials

- Maintaining 100% controlled wood for production purchasing

- Maintaining a high share of 90% of wood for production from domestic sources

- Aiming for a deforestation-free supply chain

TARGET 1:

Increasing the total wood yield of wood used in production in each plant to a minimum of 90% in 2025. Baseline: 82% in 2020

TARGET 2:

Increasing the share of post-consumer recycled wood from 40% (2020) to 60% (2030)

TARGET 3:

Manufacturing 10% of wood-based materials using biogenic binder content by 2025

TARGET 4:

Develop specific indicators to assess water consumption and waste generation in accordance with CSRD

TARGET 5:

Create a biodiversity management plan by 2025 for all production sites in or adjacent to areas with a nature protection status

TARGET 6:

Identify and mitigate potentially negative impacts on biodiversity in our wood supply chain by 2025

TARGET 7:

Document 80% of suppliers to have signed our Code of Conduct for Suppliers by 2025

Climate

PRINCIPLES

- Sustainable production

- Renewable energy

- Net-zero CO2 emissions

COMMITMENTS

- Offering a wide range of low-emission and environmentally friendly products

- Achieving net-zero CO2 emissions by 2050

TARGET 1:

Reducing Scope 1 and Scope 2 greenhouse gas emissions by 21% by 2025 (baseline 2020)

TARGET 2:

Reduce fossil fuel consumption of our own fleet by 5% by 2030

TARGET 3:

Reducing indirect greenhouse gas emissions associated with purchased chemical products used in our wood-based panels by 21% by 2025 (baseline 2020)

TARGET 4:

Switching the whole fleet to comply with the EU emission standard 6e by 2025

People

PRINCIPLES

- Fair and motivating working conditions

- Doing what is right

- Loyal and engaged stakeholder

COMMITMENTS

- Acting ethically, respectfully and responsibly towards all employees and external partners

- Applying the precautionary principle to prevent illness and accidents

- Promoting development opportunities for all our employees

- Keep the high near-miss reporting rate of one near-miss reported per employee per month

TARGET 1:

Reducing employee and contractor accidents and achieving a lost-time accident frequency rate for each of 0.5 per 200,000 hours worked (LTA-FR2) by 2025

TARGET 2:

Increase the share of employees participating in the near-miss reporting to 75% in 2025

TARGET 3:

By 2025, 100% participation of staff in compliance training as well as documentation of such training

TARGET 4:

Achieve at least 25% women on the Executive Board of Pfleiderer Deutschland GmbH by 2027

OUR PLACE IN THE CIRCULAR ECONOMY

Wood is the most sustainable building material – a renewable resource that stores huge amounts of carbon, and we recycle it to create effective, premium products. Our role in a sustainable, circular wood ecosystem ensures that every piece of wood has an extended lifecycle – adding maximum value, while having minimal impact.

Our role in a sustainable circular economy for wood ensures that each piece of wood remains in the life cycle for as long as possible - adding maximum value, while having minimal impact.

In addition, the wood-based materials industry is committed to making a significant contribution to the fight against climate change by reducing CO2 emissions through storage and substitution.

Through the consistent implementation of our recycling strategy, in 2023, we achieved our 2025 target of 50% ahead of schedule: 51% post-consumer recycled wood in our wood mix across our entire product portfolio. In 2024, we were able to increase this share to 54%.

Followed is the post-consumer recycled fraction by the fraction of sawmill residues with 25%. Thinnings and damaged wood account for 21% and, since 2007, have been sourced exclusively from controlled sources in Germany and neighbouring countries. Internal and external audits are carried out annually to ensure that the underlying criteria for FSC® Controlled Wood and PEFC Controlled Source are met throughout the supply chain. We close the loop by using recycled wood at the end of its useful life to generate thermal energy at our sites.

In 2024, we achieved wood yields of 87% to 92% in our plants, depending on the plant (2020: 81% to 91%). The current technology does not allow 100% elimination of impurities from the wood. However, based on our ongoing research and development, we consider a higher share feasible. By 2025, we aim to achieve and maintain a minimum of 90% in all production plants. Ongoing dialogue with other parties who can help us achieve this goal is a component of our strategic approach.

OUR CASCADING USE OF WOOD

SUSTAINABLE FORESTRY

We are able to process 1.4 million tonnes of wood in the “absolutely dry” category (atro) per year, plus 9,000 tonnes of decor paper. Since 2007, we have been using fresh wood and decor paper, e.g. for panel decors and cores, exclusively from controlled sources.

Internal and external audits are conducted annually to verify that the underlying criteria of FSC® Controlled Wood and PEFC Controlled Sources are met throughout the entire chain of custody.

Suppliers who do not meet the audit requirements or who do not allow our auditors access to their harvesting areas, even after signing confidentiality declarations, are consistently excluded.

We predominantely procure recycled wood from certified recycling companies. From sawmills, we obtain sawmill residues in the form of edge trimmings, wood chips, and sawdust, which are produced during the manufacture of beams and boards. Fresh industrial wood in the form of thinnings and damaged wood from windthrow and beetle infestation areas forms the smallest part of our wood raw materials.

We produce new particleboard from these raw materials and supply it to our customers. When the products have reached the end of their service life, specialist recycling companies process them and remove material components that do not belong to the same type. At our locations, we remove the remaining impurities from the recycled wood that has been processed in this way.

We use the high-quality recycled wood for the production of new wood-based products. Wood that can no longer be recycled is converted into thermal and electrical energy in our integrated biomass power plants in Gütersloh, Neumarkt and Baruth.

We use this energy in our production processes and feed surplus electricity and heat into the public electricity or heating grid. We ensure short transport routes for all raw material purchases. By establishing further partnerships with certified recycling companies, furniture manufacturers, suppliers and customers, we specifically promote the cascading use of wood and the circular economy in order to further increase the proportion.

We source the majority of our wood raw materials for production from Germany. 500 active suppliers, ranging from small regional forestry operations, sawmills and recycling companies to international suppliers, ensure a constant supply to our sites. The FSC and PEFC labels confirm that products containing wood fibre meet these criteria throughout the chain of custody (CoC).

Licence codes: FSC® (FSC C011773) and PEFC (PEFC/04-32-0828)

What do FSC and PEFC cover?

The Chain of Custody certification is a mechanism to prove responsible sourcing from forest to end-user. It ensures that materials and products have been checked at every stage of processing so that customers purchasing FSC or PEFC labelled products can be confident that they are genuinely certified.

A certified product designation means that processed virgin material either originates in certified forests or is verified as having a low probability of containing fibre from illegally harvested wood, wood harvested in violation of traditional and human rights, wood harvested from forests in which high conservation values are threatened by management activities, wood from forests being converted to plantations or non-forest use and wood from forests in which genetically modified trees are planted.

Reclaimed materials are acceptable under these certification systems, enabling us to gain value from what some consider to be waste, and ensuring the wood is put to good use before becoming fuel for process heat and power.

Read more about sustainability at Pfleiderer

We are opening another chapter on our way to more transparency in sustainability with our Sustainability Report in reference to GRI.

These topics may also be of interest to you: