Installation

- Installation is possible both vertically and horizontally

- For load-bearing walls, please choose panels that are at least equal to the wall height

- For horizontal installation, reinforce all contact points and free edges with stiffening ribs

Parting lines

- Keep a distance of at least 25 mm between the construction and the substrate (e.g. concrete) so that no water is absorbed

- To do this, place the entire construction on wedge-shaped supports and fill the joint with cement mortar

- If a separation joint is not possible, use chemical protection (impregnation)

- Panels must always be raised 25 mm above the subfloor level

- Provide expansion joints of at least 3 mm between walls and around doors and windows

Fastening

- Nails with a length of 2.5 times the thickness of the inserted panel, at least 50 mm, preferably spiral or convex nails.

- Wood screws with a length of 2.5 times the thickness of the inserted board, at least 45 mm; at least 4.2 x 45 mm are recommended.

Recommended distances of the fixing points (nails or screws):

| Panel thickness | At the panel edges | Inside the panel |

| 9 – 12 mm | 100 mm | 200 mm |

| 12 – 15 mm | 125 mm | 250 mm |

| 15 – 22 mm | 150 mm | 300 mm |

If walls transmit loads, the distance between the fixing points must be determined by static calculation.

Moisture

For exterior walls, the use of ventilated curtain walls is recommended, as these allow a constant air exchange and moisture removal through the rear ventilation. For panels attached to the outside of exterior walls, the diffusion resistance of the panel must be taken into account with regard to the penetration of water vapour. On interior walls, the boards can serve as diffusion resistance, provided that the connection between them and the other construction elements is sealed with suitable adhesive tape (see p. 61, Moisture protection). When using tongue-and-groove boards, this sealing can also be done with PUR or PVAC glue. In any case, the entire construction must be provided with an insulating coating against water penetration in all contact surfaces.

Handling and processing instructions

All Pfleiderer panel types can be sawn, planed, milled, drilled and sanded with the usual woodworking machines or woodworking tools. We recommend carbide-tipped tools for this purpose.

Installation and assembly

Sufficient conditioning is required before processing and installation. The rooms themselves must be air-conditioned according to the subsequent use.

Ripping and sawing

Pfleiderer panels offer the best conditions for high-quality processing with all common saws. We recommend carbide-tipped saw blades. Optimum results with MDF are achieved with a rake angle of 8 to 10° and a cutting speed of 40 to 80 m/s.

Drilling

Tools and materials must be used for all drilling, that are also used for plywood and solid wood panels.

Screw

Screws should generally be pre-drilled. Recommended diameter is the same as the core diameter of the screw thread. of the screw thread. When screwing, the distance to the edge of the panel should be at least 20 mm.

Connection technology

All conventional detachable and non-detachable fasteners for solid wood and connectors for solid wood and wood-based materials.

Storage and transport

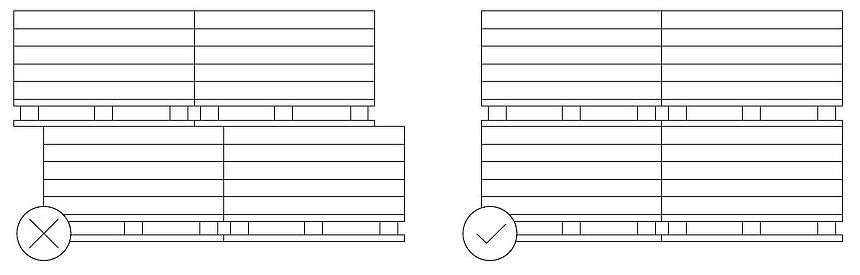

The following instructions should be observed when storing or transporting wood-based materials:

- Wood-based materials should preferably be stored horizontally and without direct contact with the ground on dry storage lumber.

- The top board should be covered with a protective board or cardboard over the entire surface. Sufficient distance to walls should be maintained, direct contact should be avoided.

- If several stacks of boards are stacked on top of each other, make sure that squared timbers are used as intermediate battens after every 15 to 20 boards to allow air movement. Support timbers of the same thickness are to be used, which are to be placed at equal distances from each other (max. 80 cm) in vertical alignment. This rule applies to boards with a thickness of 15 mm or more. For thinner boards, smaller support distances should be chosen.

- The panel overhang at the end of the stack should not exceed 150 mm.

Would like to learn more?

Feel free to contact us directly! We look forward to hearing from you.