Availability

Overview of available formats

| Length (mm) | Width (mm) | Thickness (mm) | Surface texture |

|---|---|---|---|

| 2,800 | 2,070 | 4 | 6 | 7 | 8 | 10 | 12 | 13 | 15 | HG | MP | SD | SM | VV |

Certificates & labels

Product features

Areas of application

- For universal use in preventive fire protection to reduce the spread of flame. Particularly useful where non-flammable materials are required and high demands are made on the design and ease of care. The area of application covers decorative interior fitting as furniture, installations and wall coverings in corridors and stairways (escape routes) in standard buildings, but also for higher demands in special buildings such as high-rise apartment blocks, large office buildings, hospitals, care facilities, schools, day nurseries, hotels, sales rooms and public areas, etc. Use in wet areas and outdoors, as well as mechanical surface stress, is not recommended.

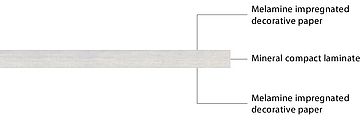

Core material

- Mineral compact laminate: Compact core of primarily mineral constituents with outstanding strength properties. Suitable for areas subject to particularly high demands of fire protection.

Density

- 1,900 kg/m³

Reaction to fire

- Non-combustible

- A2-s1,d0 (EN 13501-1)

Formaldehyde emission class

- E1 E05

Antimicrobial effect

- Surface with antimicrobial effect in 24 h for interior fit-out and finishes – Test Methodology JIS Z 2801 / ISO 22196

Product safety

- This product follows the REACH regulation EC 1907/2006 an article. Following Article 7 it does not need to be registered.

- The surface is physiologically safe, and approved for direct contact with food acc. to Regulation (EU) No. 10/2011.

- The decorative surface consists of paper layers and a mineral material core, which are impregnated with thermosetting resins. The resins harden completely during the manufacturing process by heat and high-pressure. They form a stable, resistant and non-reactive material.

Special

- Please comply with information for the Duropal flameprotect compact collection at www.pfleiderer.com.

Colour and surface match

- Decor, structure and core board all influence the final appearance of the end product.

- Due to the product-specific differences in production technologies, even identical decor/structure/core board combinations can result in slight optical and tactile deviations across different product groups and formats. Such deviations do not constitute a defect.

- The choice of surface structure in particular has a significant influence on the visual impression, the tactile perception as well as the technical characteristics of the product. Thus, the overall impression of a decor can change almost completely depending on the surface structure. Furthermore, mechanical influences on the product surface can lead to a higher contrast optical perception with dark decors.

- To ensure that you always achieve the best results with our products and to clarify any deviations in advance, we will be happy to advise you individually.

Additional information

Product handling

Machines and tools

- Machining can be carried out on all common machining equipment and processing apparatus.

- Cut-to-size saw:

– cutting speed: 65–75 m/sec

– infeed: up to 10 m/min for single cuts, up to 7 m/min for pallets of boards

– saw blade projection: 15 – 30 mm

sizing circular saw:

- cutting speed: 65–75 m/sec

– infeed: up to 10 m/min for single cuts, up to 7 m/min for pallets of boards

– saw blade projection: 15 – 30 mm - Diamond tipped tools are suitable for machining and processing.

Edging

- It is generally recommended to seal the edges. If required, you can find further information from the fire protection sub-standard DIN EN ISO 1716.

- The narrow glue surface must be absolutely dust-free or pre-treated with a primer.

- The edge strength test should only be carried out after a few minutes, not immediately after starting.

- PUR hotmelts are recommended for edge adhesion.

Fitting technology

- All conventional removable and non-removable fittings for wood materials, compact laminates and mineral boards are suitable.

- Under the general building inspectorate approval, connections and fastenings with adhesive systems are not permitted for applications.

- Under mounts can also be used for fixing wall coverings, e.g.

Fa. Keil Fixing Technology GmbH, Suitable for invisible panel fastening solutions - e.g. undercut anchor technology, Link: https://www.keil-fixing.de/

Fa. Fischer Germany Sales GmbH, Suitable for invisible panel fastening solutions - e.g. undercut anchor technology, Zxkon panel anchor FZP II T PA - for HPL compact panels and mineral material panels, Link: https://www.fischer.de/ - Suitable fittings or screws that are suitable for a maximum end panel thickness of up to 15.0 mm must be used for furniture production.

Installation and assembly

- Please always ensure proper machining and installation according to the current available technology. Special attention must be paid to the material properties given its high mineral content.

- Sufficient conditioning is required prior to installation. The premises themselves need to be air-conditioned according to the future use.

- Ensure good rear ventilation and climate equilibrium on both sides in the installed condition. For adequate air circulation the void should be at least 20 mm. It is important to interrupt horizontal substructures as well as the top and bottom ends of the wall panelling so that vertical rear ventilation is possible. Avoid direct fixing on the surface without air gap.

- The base may not be moist or unstable. Please make sure that minimum carrying capacity and stability correspond to the usage.

- Newly built walls (made of brick or concrete or plastered walls) contain considerable amounts of moisture. Before covering them with panels they must be completely dried out.

- Ensure that there is an adequate area of “play” for the panel after installation; drill holes should be over-sized by a minimum of 0.5 mm.

- It is essential to ensure that the expansion area of all installed Duropal flameprotect compact is not impeded. When combined with different or the same materials, the potentially different expansion coefficients must be taken into account in the event of climatic changes.

- Make sure that expansion of installed elements is not prevented. Please observe that when panels are combined with other materials their coefficients of expansion may differ.

- Please also refer to the current building inspection regulations. Panels must be mechanically fixed on the base with non-flammable fastenings.

- Duropal flameprotect compact has no constructive properties

- Especially for large applications, we recommend paying attention to the colour and texture uniformity of the boards and cut products used when further processing and installing and that the production direction is taken into account.

- Avoid direct fixing on the surface without air gap.

- The substructure must be protected against corrosion and must be made of non-combustible materials.

Storage, handling and transport

- Panels must be fully and horizontally stored with edges flush on a flat and clean base covered with plastic foil. Cover the top panel fully with foil and a cover board.

- Protect from moisture and wet conditions.

- Avoid direct exposure to heat and any possible dehydration of the surfaces by light- or heat radiation or by air currents from heating- or air conditioning systems.

- Foreign bodies or impurities in the pallet of sheets can lead to impressions and damage to the surface of the board.

- Sheets / boards must not be moved against each other, they should be moved individually by hand or with suction equipment.

- Ensure that sufficiently large and sturdy bases, e.g. pallets, are used for the transportation of stacked sheets. The sheets on the pallet must be secured against slipping.

Health and safety

- Provide adequate extraction when splitting / sanding.

- Provide adequate ventilation and fresh air supply.

- Suck (vacuum) dust when cleaning; do not blow.

- Work clothes should cover the body entirely (trunk, legs and arms) whilst processing these panels.

- Use the usual products for skin protection (creams etc.).

- We advise operators to wear a face mask (P2).

- Please wear the appropriate personal protective equipment (PPE) when processing and handling.

Cleaning and care

- The surface can be cleaned with water and gentle cleaning agents.

Disposal

- When machining large quantities, we advise using a separate saw dust extraction. Offcuts and large amounts of saw dust are to be collected and disposed of separately.

- Waste code for disposal: 030199

Would you like to learn more?

Please get in touch with us! We look forward to hearing from you.

References

Samples

Decor and texture

Product

Format