Availability

Overview of available formats

| Length (mm) | Width (mm) | Thickness (mm) |

|---|---|---|

| 2,800 | 2,070 | 1.2 |

Certificates & labels

Product features

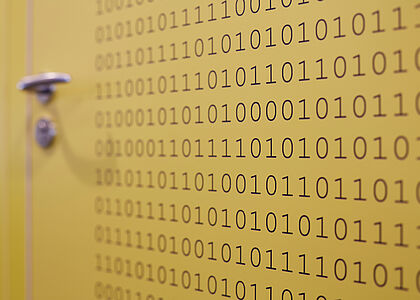

Areas of application

- Furniture, partition walls and wall coverings with magnetic properties in shop and trade fair construction, in offices, schools, day nurseries, care home facilities, public facilities, etc.

Product standard

- In accordance with EN 438-9

Density

- Min. 2,200 kg/m³

Reaction to fire

- Normally flammable

- Euroclass D-s2,d0 or worse in connection with normally and easily inflammable core boards. (EN 13501-1, CWFT conforming to 2003/593/EG)

Formaldehyde emission class

- E1 E05

Antimicrobial effect

- Surface with antimicrobial effect in 24 h for interior fit-out and finishes – Test Methodology JIS Z 2801 / ISO 22196

Product safety

- This product follows the REACH regulation EC 1907/2006 an article. Following Article 7 it does not need to be registered.

- The surface is physiologically safe, and approved for direct contact with food acc. to Regulation (EU) No. 10/2011.

- The decorative surface and the core consists of paper layers, which are impregnated with thermosetting resins. The resins harden completely during the manufacturing process by heat and high-pressure. They form a stable, resistant and non-reactive material.

- We manufacture the panels without the use of organohalogens, heavy metals, preservatives, wood protectors or organic solvents.

Special

- Full-size boards have a non-magnetic, visible border approx. 30 mm wide.

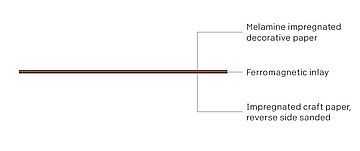

- Due to the insertion of the metal mesh (ferromagnetic inlay), there will be optical deviations in the structure compared to standard products.

- Cut to size is not available.

- HG texture is recommended for writing on with standard board markers, textures VV and MP for writing on with blackboard chalk.

- Real metal surfaces are not possible.

- FSC certification or PEFC certification available on request.

Colour and surface match

- Decor, structure and core board all influence the final appearance of the end product.

- Due to the product-specific differences in production technologies, even identical decor/structure/core board combinations can result in slight optical and tactile deviations across different product groups and formats. Such deviations do not constitute a defect.

- The choice of surface structure in particular has a significant influence on the visual impression, the tactile perception as well as the technical characteristics of the product. Thus, the overall impression of a decor can change almost completely depending on the surface structure. Furthermore, mechanical influences on the product surface can lead to a higher contrast optical perception with dark decors.

- To ensure that you always achieve the best results with our products and to clarify any deviations in advance, we will be happy to advise you individually.

Product handling

Processing

- Single sheet cut with the decorative side facing up.

- In general watch out for flying sparks! Switch-off any extraction / vacuum.

- We recommend that the boards to be processed are earthed to avoid electrostatic charges.

- Please pay attention on your cutting plan to the 30 mm wide, non-magnetic edge of the boards.

- For the production of flat-bonded panels we recommend a symmetric construction. This means both sides should be identical HPL. If backing material (also HPL) is used, there is a risk of bowing.

- Please respect the recommendations of BLFA (www.blfa.co.uk) an ICDLI (www.icdli.com) for the processing of high-pressure laminates.

- Trial cuts are recommended.

Machines and tools

- Machining can be carried out on all common machining equipment and processing apparatus.

- All carbide tipped tools with firmly soldered blades and drawing cut are suitable, do not use diamond tools.

- Metal inserts lead to reduced tool life.

- Processing with circular trimming saw with parallel stop:

- TC-tipped circular sawblade Leitz ‚FerroFix’, tooth shape FZFA/FZFA, ID No. 2000636 / 2000322

- RPM: 1000 U/min

- Feed rate: 5 m/min

- Tooth feed rate: 0,06 mm

- Cutting Speed: 18,8 m/s

- Sawblade protrusion: 15 - 20 mm

- Scorers suitable for the saw blade are to be used, the cutting speed should also be approx. 20 m/s

- Vibrations in the board are generally to be avoided - Working with machining centres:

– Sawblade Leitz ‚DryCut’, tooth shape FZFA/FZFA, ID No. 169002 / 169003 / 169004 / 169005

– RPM: 1350 U/min

– Feed rate: 3 m/min

– Tooth feed rate: 0,03 mm

– Cutting Speed: 18,0 m/s

– Score in down-cut

– Cut in up-cut

– Vibrations in the board are generally to be avoided

– Saw blade running is to be checked first – if necessary make adjustments to the machine (spindle – saw blade)

Installation and assembly

- Sufficient conditioning is required prior to installation and assembly. The premises themselves need to be at the normal climatic conditions in which the material will later be used.

- Please ensure that the material is processed and fitted correctly and using the best available technology.

Storage, handling and transport

- The material must be stored flat, level and horizontal on clean surfaces at normal climatic conditions (Temperature 18–25 °C, relative humidity 50–65 %).

- Protect from moisture and wet conditions.

- Avoid direct exposure to heat and any possible dehydration of the surfaces by light- or heat radiation or by air currents from heating- or air conditioning systems.

- Foreign bodies or impurities in the pallet of sheets can lead to impressions and damage to the surface of the board.

- Sheets / boards must not be moved against each other, they should be moved individually by hand or with suction equipment.

- Ensure that sufficiently large and sturdy bases, e.g. pallets, are used for the transportation of stacked sheets. The sheets on the pallet must be secured against slipping.

- Please note that incorrect storage, regardless of its duration, may cause irreversible distortion to the sheets.

Health and safety

- Please wear the appropriate personal protective equipment (PPE) when processing and handling.

- Provide adequate extraction when splitting / sanding.

Cleaning and care

- The surface can be cleaned with water and gentle cleaning agents. To remove stubborn stains, please observe the recommendations in the data sheet "Cleaning of HPL surfaces" (www.icdli.com).

Disposal

- We recommend material or energy recovery in approved plants.

Would you like to learn more?

Please get in touch with us! We look forward to hearing from you.

References

Samples

Decor and texture

Product

Format