Availability

Overview of available formats

| Length (mm) | Width (mm) | Thickness (mm), HPL 0.8 mm |

|---|---|---|

| 2,800 | 2,070 | 9.6 | 16 | 17.6 | 19 | 20.6 | 23.6 | 25 | 29.6 | 39.6 |

| 4,100 | 1,300 | 9.6 | 16 | 17.6 | 19 | 20.6 | 25 | 29.6 | 39.6 |

Certificates & labels

Product features

Areas of application

- Surface material for vertical applications with authentic metal character in high quality interior design and shop fitting, in trade fair construction, but also in the private residential sector. Real aluminium surfaces are not suitable for horizontal applications and/or surfaces exposed to mechanical loads.

Product standard

- In accordance with EN 13894-2

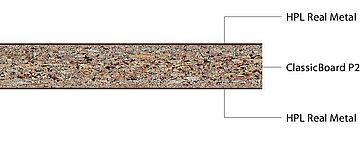

Core material

- ClassicBoard P2: Urea resin-bonded particleboard, type P2 conforming to EN 312, suitable for non load-bearing purposes in dry areas.

Reaction to fire

- Normally flammable

- D-s2,d0 (EN 13501-1, CWFT conforming to 2003/593/EG)

Formaldehyde emission class

- E1 E05

- TSCA Title VI

Product safety

- This product follows the REACH regulation EC 1907/2006 an article. Following Article 7 it does not need to be registered.

- The decorative surface is a lacquered aluminium foil. The material core consists of paper layers which are impregnated with a duroplastic resin. The resins harden completely during the manufacturing process by heat and high-pressure. They form a stable, resistant and non-reactive material.

- We manufacture the panels without the use of organohalogens, heavy metals, preservatives, wood protectors or organic solvents.

Special

- Please note: with format 2,800 x 2,070 mm the visible longitudinal joint of the real metal foil (2 strips) at approx. 1,380 mm and the usable length of min. 2,780 mm.

- Cut to size is not available.

- Real metal surfaces are generally delivered with a protective foil resistant to temperatures of up to 80°C. The protective foil must be removed six months after delivery at the latest.

- Available in design M80000 Alu 1, Stainless Steel Effect and M80001 Alu 2, Nickel Effect.

- FSC certification or PEFC certification available on request.

Colour and surface match

- Decor, structure and core board all influence the final appearance of the end product.

- Due to the product-specific differences in production technologies, even identical decor/structure/core board combinations can result in slight optical and tactile deviations across different product groups and formats. Such deviations do not constitute a defect.

- The choice of surface structure in particular has a significant influence on the visual impression, the tactile perception as well as the technical characteristics of the product. Thus, the overall impression of a decor can change almost completely depending on the surface structure. Furthermore, mechanical influences on the product surface can lead to a higher contrast optical perception with dark decors.

- To ensure that you always achieve the best results with our products and to clarify any deviations in advance, we will be happy to advise you individually.

Product handling

Processing

- Can be worked with carbide tipped tools on conventional woodworking machines.

- Processing with protective foil is recommended. Dirt inclusions as well as heavy or sharp objects can leave pressure marks on the surface.

- If processed with the protective foil in place, please observe the longitudinal orientation of the decor surface and the longitudinal butt joint of the real metal film at approx. 1,380 mm (2 films) in size 2,800 x 2,070 mm.

- Face side face up on machining table, flashes can be removed using a fine file or sandpaper. Avoid flashes by using a pulling cut, and mill at a low speed, preferably synchronised.

Machines and tools

- We recommend the use of fixed machinery.

Edging

- Thick and thin edges are suitable.

- EVA and PUR hotmelts are recommended for edge adhesion.

Fitting technology

- All conventional removable and non-removable fittings for solid wood and wood materials are suitable.

Installation and assembly

- Real metal surfaces are generally delivered with a protective foil resistant to temperatures of up to 80°C. The protective foil must be removed six months after delivery at the latest.

- For side-by-side installations in interior fitting, real metallic surfaces from the same production batch are to be used. If there is some space between applications, different batches may also be used.

- Sufficient conditioning is required prior to installation and assembly. The premises themselves need to be at the normal climatic conditions in which the material will later be used.

- Please ensure that the material is processed and fitted correctly and using the best available technology.

- Especially for large applications, we recommend paying attention to the colour and texture uniformity of the boards and cut products used when further processing and installing and that the production direction is taken into account.

Storage, handling and transport

- On level, full area surfaces (e.g. pallets), protected against moisture, in dry, ventilated rooms. Outdoor storage is not suitable.

- Please note that incorrect storage, regardless of its duration, may cause irreversible distortion to the sheets.

- Foreign bodies or impurities in the pallet of sheets can lead to impressions and damage to the surface of the board.

- Ensure that sufficiently large and sturdy bases, e.g. pallets, are used for the transportation of stacked sheets. The sheets on the pallet must be secured against slipping.

- Sheets / boards must not be moved against each other, they should be moved individually by hand or with suction equipment.

Health and safety

- Please wear the appropriate personal protective equipment (PPE) when processing and handling.

Cleaning and care

- Any type of stains must be removed immediately. Slight soiling shall be removed with a moist cloth and a neutral/intensive cleaner. Always use only soft cleaning cloths even on stubborn dirt. The surface must be cleaned with a clean cleaning cloth afterwards. Do not use solvents or harsh cleaning agents!

- The use of cleaning products, cloths, sponges with abrasive ingredients, should be avoided.

- The surface can be cleaned with water and non-aggressive cleaning products. For more detailed information, please refer to our "Cleaning recommendation Decorative Pfleiderer products".

- For further information, please follow the recommendation in the "Cleaning HPL" leaflet on the site www.icdli.com.

Disposal

- We recommend material or energy recovery in approved plants.

Would you like to learn more?

Please get in touch with us! We look forward to hearing from you.

Samples

Decor and texture

Product

Format

Info material

Title

Type

Format

Hygieneprodukte – antimikrobielle und antivirale Oberflächen

Brochure

Format:

--