SUSTAINABLE MATERIALS, BUILDING SERVICES AND CONSTRUCTION METHODS WORKING TOGETHER IN PERFECT HARMONY

An experts project by builder Hans-Jürgen Kremer

My goal is to promote timber construction. This almost always involves the interaction of people, technologies, experience and materials. For my vision of a timber house with a pioneering living environment, I rely on Pfleiderer because PremiumBoard MFP Living P5, with its sanded surface, is the best basis I know for wall coating with clay!

My goal is to promote timber construction. This almost always involves the interaction of people, technologies, experience and materials. For my vision of a timber house with a pioneering living environment, I rely on Pfleiderer because PremiumBoard MFP Living P5, with its sanded surface, is the best basis I know for wall coating with clay!

My goal is to promote timber construction. This almost always involves the interaction of people, technologies, experience and materials. For my vision of a timber house with a pioneering living environment, I rely on Pfleiderer because PremiumBoard MFP Living P5, with its sanded surface, is the best basis I know for wall coating with clay!

My goal is to promote timber construction. This almost always involves the interaction of people, technologies, experience and materials. For my vision of a timber house with a pioneering living environment, I rely on Pfleiderer because PremiumBoard MFP Living P5, with its sanded surface, is the best basis I know for wall coating with clay!

My goal is to promote timber construction. This almost always involves the interaction of people, technologies, experience and materials. For my vision of a timber house with a pioneering living environment, I rely on Pfleiderer because PremiumBoard MFP Living P5, with its sanded surface, is the best basis I know for wall coating with clay!

Pfleiderer in conversation with Hans-Jürgen Kremer

Pfleiderer: Mr Kremer, what is so special about your house?

Hans-Jürgen Kremer : I would say: everything! There is no one aspect that I would particularly like to highlight. What is much more important is that a variety of sustainable materials, building services and construction methods come together in harmony – creating a home that offers my wife and me an optimal living environment in every respect.

Pfleiderer: What does that mean specifically? There are many timber-framed houses. Can you explain a little about what is different about your home?

Hans-Jürgen Kremer: Gladly! I have spent a lot of time and energy finding the best possible solution for all the issues that are important to me. This includes the construction method itself, the building services used and also the interior design. It's about both the ecological footprint and the potential quality of life.

Pfleiderer: Clay plays an important role in this, right?

Hans-Jürgen Kremer: Exactly. I built a wooden house 20 years ago, which I was basically quite happy with. But the current one is a big step in the right direction. Back then, clay wasn't an issue for me, but today I work for Conluto, a supplier of clay and clay products for the construction sector that is 100% committed to sustainability and quality of living. It was clear to me that this time I definitely wanted to use clay for the interior design – and not plaster!

Pfleiderer: What is the problem with plaster?

Hans-Jürgen Kremer: On the one hand, there is the ecological dimension. Gypsum and gypsum plasters are natural products, but on closer inspection it becomes clear that gypsum products are hardly sustainable. This is because they either come from coal-fired power stations as flue gas desulphurisation gypsum or are extracted from quarries or underground mines. With the phase-out of coal, the first source is disappearing and natural mining is increasing. This has an impact on the landscape and ecosystems, which then have to be renaturalised at great expense. The burning process required to manufacture plasterboard or plaster also generates CO2 emissions in any case. So there is more than one reason to avoid plaster.

Pfleiderer: And clay is better here?

Hans-Jürgen Kremer: Absolutely: it is usually extracted regionally, which means that it has less impact on the landscape. As it is only dried and not fired, the energy consumption is also significantly lower. And – for me, a very decisive aspect – clay is also superior to plaster in almost all areas of indoor climate control: it regulates humidity better, stores more heat, binds pollutants and odours, and its higher weight and open-pored structure also allow it to dampen sound better.

Pfleiderer: So, all the interior walls in your house are plastered with clay?

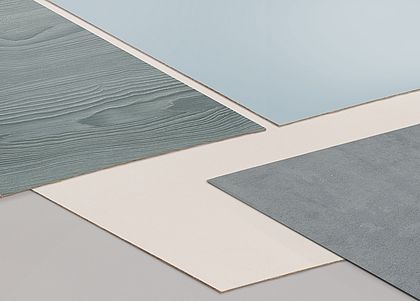

Hans-Jürgen Kremer: Yes, we opted for an interior wall construction in which the clay is applied directly to the wood-based surface. We have had the best experience with PremiumBoard MFP Living P5. BioSol Naturbau GmbH, who carried out the interior work, had previously used other boards, but the surface quality of the Pfleiderer board was impressive. Going forward, this means Pfleiderer will likely be the brand of choice. In our wall construction, a reed mat is first attached to the board surface. A 15 mm layer of clay is then applied. Once it has dried, the final coat is applied with a 2 mm layer of fine plaster. Here, too, we remain true to the principle of ecology, as Conluto's fine plaster consists of coloured clay and loam, with mixed-grain sand and cellulose added in some cases. The result is a highly aesthetic, easy-care and, above all, open-pored wall with the aforementioned positive properties in terms of indoor climate.

Pfleiderer: Was this finish also used on the inside of the exterior walls?

Hans-Jürgen Kremer: Of course! We constructed the exterior walls from 80/200 mm KVH beams, which are reinforced on the inside with PremiumBoard MFP Living P5. On the outside, we used 60 mm thick wood fibre insulation boards. Lathing and counter-lathing were attached to these, and finally a rear-ventilated curtain façade (VHF) made of thermally treated silver fir was installed.

Pfleiderer: You're not easily satisfied with standards, are you?

Hans-Jürgen Kremer: Well, I'm from the industry and have come across many excellent solutions over the years. I'm a big networker, which means I bring people and companies together to share knowledge, make good solutions even better and promote new partnerships. PremiumBoard MFP Living P5 for wall construction is just one example. Our colleagues at Anton Holzbau GmbH in Morbach already had the panel in their range, but the interior designers at BioSol were more than pleasantly surprised. Also, anyone who is into timber construction and has seen Swero's façade timber will, in my opinion, simply not be able to get it out of their head. The wood is sourced sustainably from the region and treated exclusively with steam and heat, without any chemicals or chemical processes. In my case, it is then pre-greyed, which means – to put it simply – that it is weathered in a controlled manner on the meadows of the Allgäu region in the great outdoors. This means that, unlike wood treated with pre-greying glazes, it continues to develop evenly and harmoniously in terms of colour.

Pfleiderer: Are there any other special features we should point out?

Hans-Jürgen Kremer: That depends on how much detail we want to go into. The interior walls, for example, are equipped with special blow-in insulation made of pure cellulose. But not just any cellulose, but that from IQ3. This is a Belgian manufacturer that uses only recycled daily newspapers. Only "clean" waste paper is sorted by type and pre-treated against flammability and pests. This means that the blow-in insulation even meets the strict criteria of the natureplus eco-label! In this context, it may also be worth mentioning the floor slabs. They are simply made of solid structural timber (KVH), as we also wanted to avoid using screed and separate floor coverings.

Pfleiderer: But wouldn't it make sense in terms of sustainability to use underfloor heating with a heat pump or similar?

Hans-Jürgen Kremer: Here, too, we are taking a slightly different approach, as you may have guessed. The house is supplied with electricity via a photovoltaic system on the roof. We use the electricity, among other things, to heat the house with infrared wall heating panels. This prevents dust from being stirred up, as is usually the case with underfloor heating. As we comply with the highest energy efficiency standards, the infrared heating for our home is fully compatible with the requirements of the Building Energy Act (GEG). Thanks to the excellent temperature-regulating effect of the clay plaster, we have even been able to dispense with active living space ventilation. We simply feed in surplus electricity, whereby our favourable location not far from the Moselle valley enables us to achieve an exceptionally good photovoltaic yield. Another advantage of PremiumBoard MFP Living P5 becomes apparent when installing the wall heating modules: the heating modules, which weigh approx. 40 kilograms, can be easily anchored in the panel.

Pfleiderer: Allow me to ask about construction costs and time. Did the many special features make your house more complex and expensive than comparable properties?

Hans-Jürgen Kremer: I can say with certainty that this is not the case. The house, with a living area of approx. 220 m² and a practice located on the ground floor like a granny flat, cost us the same as a conventional construction. As for the construction time: " " Thanks to extensive prefabrication, it took us almost exactly five months after the floor slab was completed – try beating that. The prefabricated elements were assembled on site using traditional connectors. The whole thing is robust and, if necessary, very easy to maintain – although I firmly believe that no maintenance will be required in the foreseeable future.

Pfleiderer: Mr Kremer, as a perfectionist, what would you do even better with your next house?

Hans-Jürgen Kremer: Good question... I think I'm satisfied for now (laughs). In our new home, we've implemented many of the improvements I noticed in our last house.

Pfleiderer: Thank you very much for talking to us!

Profile Hans-Jürgen Kremer

„As a networker, I bring people and companies together to share knowledge, make good solutions even better and promote new partnerships.“

Hans-Jürgen Kremer

Client

The facts about the project

| Project: | Detached house with integrated practice |

| Product: | PremiumBoard MFP Living P5 |

| Area of application: | Reinforcing interior wall panelling |

| Client: | Hans-Jürgen Kremer, Binningen |

| Timber construction: | Anton Holzbau GmbH Idarwaldstr. 10A 54497 Morbach |

| Interior design: | BioSol Naturbau GmbH Joseph-von-Fraunhofer-Str. 21-23 53501 Grafschaft |

| Photographs: | Christoph Gerhartz |

Products used

Individual Advice

Contact

Please contact us directly! We look forward to hearing from you.

Product inquiries and sales.

+49 (0) 9181 28-480