Availability

Overview of available formats

| Length (mm) | Width (mm) | Thickness (mm) |

|---|---|---|

| 2,655 | 2,100 | 10 | 13 | 16 | 18 | 19 | 25 | 28 | 38 |

| 2,800 | 2,100 | 16 | 19 |

| 5,310 | 2,100 | 10 | 13 | 16 | 18 | 19 | 25 | 28 | 38 |

| 5,600 | 2,100 | 16 | 19 |

Certificates & labels

Product features

Areas of application

- Preventive fire protection in the decorative sector. For interior fitting as wall and ceiling coverings, installations, room dividers and furniture, in industrial and administrative buildings, schools, sports and festival halls, hotels and care facilities.

Product standard

- EN 14322

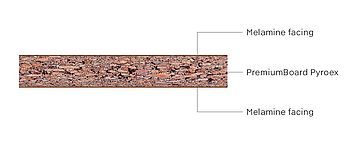

Core material

- PremiumBoard Pyroex: Flame resistant particleboard, suitable for non load-bearing purposes in dry areas, for interior fitting and for furniture subject to higher demands on fire protection.

Reaction to fire

- Flame retardant

- B-s1,d0 (EN 13501-1)

- DecoBoard Pyroex fulfills the additional specifications 'lowest smoke emission' and 'no burning droplets' and thus the highest building authority requirements for flame retardant building materials according to EN 13501-1.

Formaldehyde emission class

- E1 E05

Antimicrobial effect

- Surface with antimicrobial effect in 24 h for interior fit-out and finishes – Test Methodology JIS Z 2801 / ISO 22196

Product safety

- This product follows the REACH regulation EC 1907/2006 an article. Following Article 7 it does not need to be registered.

- The surface is physiologically safe, and approved for direct contact with food acc. to Regulation (EU) No. 10/2011.

- We manufacture the panels without the use of organohalogens, heavy metals, preservatives, wood protectors or organic solvents.

Special

- FSC certification or PEFC certification available on request.

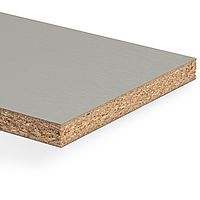

Colour and surface match

- Decor, structure and core board all influence the final appearance of the end product.

- Due to the product-specific differences in production technologies, even identical decor/structure/core board combinations can result in slight optical and tactile deviations across different product groups and formats. Such deviations do not constitute a defect.

- The choice of surface structure in particular has a significant influence on the visual impression, the tactile perception as well as the technical characteristics of the product. Thus, the overall impression of a decor can change almost completely depending on the surface structure. Furthermore, mechanical influences on the product surface can lead to a higher contrast optical perception with dark decors.

- To ensure that you always achieve the best results with our products and to clarify any deviations in advance, we will be happy to advise you individually.

Additional information

Product handling

Processing

- The fire retardant additives and colourants contained in the support can create deposits on tools and therefore reduce their durability.

The adhesion of glues can be reduced in exceptional cases.

Machines and tools

- The fire retardant additives and colourants contained in the support can create deposits on tools and therefore reduce their durability.

The adhesion of glues can be reduced in exceptional cases. - Can be worked with carbide (HW) or diamond (DP) tipped tools on conventional woodworking machines.

Edging

- Thick and thin edges are suitable.

- EVA and PUR hotmelts are recommended for edge adhesion.

Fitting technology

- All conventional removable and non-removable fittings for solid wood and wood materials are suitable.

Installation and assembly

- Sufficient conditioning is required prior to installation and assembly. The premises themselves need to be at the normal climatic conditions in which the material will later be used.

- Please ensure that the material is processed and fitted correctly and using the best available technology.

Storage, handling and transport

- On level, full area surfaces (e.g. pallets), protected against moisture, in dry, ventilated rooms. Outdoor storage is not suitable.

- Please note that incorrect storage, regardless of its duration, may cause irreversible distortion to the sheets.

- Foreign bodies or impurities in the pallet of sheets can lead to impressions and damage to the surface of the board.

- Ensure that sufficiently large and sturdy bases, e.g. pallets, are used for the transportation of stacked sheets. The sheets on the pallet must be secured against slipping.

- Sheets / boards must not be moved against each other, they should be moved individually by hand or with suction equipment.

- A protective foil must be removed as soon as possible after processing – but at the latest within 6 months after delivery – to ensure residue-free removal of the foil. In addition, foiled boards must not be exposed to direct sunlight (UV radiation).

Health and safety

- Please wear the appropriate personal protective equipment (PPE) when processing and handling.

Cleaning and care

- The surface can be cleaned with water and gentle cleaning agents.

- The use of cleaning products, cloths, sponges with abrasive ingredients, should be avoided.

- For removal of particularly stubborn stains, industrial cleaners suitable for plastic surfaces can be used. Before use we would recommend testing in a small, hidden area.

Disposal

- We recommend material or energy recovery in approved plants.

Would you like to learn more?

Please get in touch with us! We look forward to hearing from you.

References

Samples

Decor and texture

Product

Format

Info material

Title

Type

Format

Hygieneprodukte – antimikrobielle und antivirale Oberflächen

Brochure

Format:

--