Availability

Overview of available formats

| Length (mm) | Width (mm) | Thickness (mm), HPL 0.8 mm |

|---|---|---|

| 4,100 | 1,300 | 17.6 | 20.6 |

Certificates & labels

Product features

Areas of application

- Decorative, sturdy elements for furniture and interior design where a uniform core material with very high edge quality – for profiling and lacquering – is required: e. g. in restaurants and shop fitting and for office and interior furniture.

Product standard

- In accordance with EN 13894-2

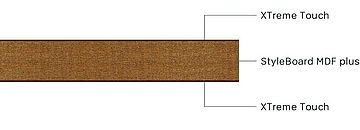

Core material

- StyleBoard MDF plus: Medium-density fibreboard (MDF), with a uniform structure.

Reaction to fire

- Normally flammable

- D-s2,d0 (EN 13501-1, CWFT conforming to 2003/593/EG)

Formaldehyde emission class

- E1 E05

- TSCA Title VI

Product safety

- This product follows the REACH regulation EC 1907/2006 an article. Following Article 7 it does not need to be registered.

- The surface is physiologically safe, and approved for direct contact with food acc. to Regulation (EU) No. 10/2011.

Special

- FSC certification or PEFC certification available on request.

Colour and surface match

- Decor, structure and core board all influence the final appearance of the end product.

- Due to the product-specific differences in production technologies, even identical decor/structure/core board combinations can result in slight optical and tactile deviations across different product groups and formats. Such deviations do not constitute a defect.

- The choice of surface structure in particular has a significant influence on the visual impression, the tactile perception as well as the technical characteristics of the product. Thus, the overall impression of a decor can change almost completely depending on the surface structure. Furthermore, mechanical influences on the product surface can lead to a higher contrast optical perception with dark decors.

- To ensure that you always achieve the best results with our products and to clarify any deviations in advance, we will be happy to advise you individually.

Product handling

Processing

- Can be worked with carbide tipped tools on conventional woodworking machines.

Edging

- Thick and thin edges are suitable.

- EVA and PUR hotmelts are recommended for edge adhesion.

Fitting technology

- All conventional removable and non-removable fittings for solid wood and wood materials are suitable.

Installation and assembly

- Sufficient conditioning is required prior to installation and assembly. The premises themselves need to be at the normal climatic conditions in which the material will later be used.

- Please ensure that the material is processed and fitted correctly and using the best available technology.

Storage, handling and transport

- On level, full area surfaces (e.g. pallets), protected against moisture, in dry, ventilated rooms. Outdoor storage is not suitable.

- Please note that incorrect storage, regardless of its duration, may cause irreversible distortion to the sheets.

- Foreign bodies or impurities in the pallet of sheets can lead to impressions and damage to the surface of the board.

- Ensure that sufficiently large and sturdy bases, e.g. pallets, are used for the transportation of stacked sheets. The sheets on the pallet must be secured against slipping.

- Sheets / boards must not be moved against each other, they should be moved individually by hand or with suction equipment.

Health and safety

- Please wear the appropriate personal protective equipment (PPE) when processing and handling.

Cleaning and care

- The surface can be cleaned with water and non-aggressive cleaning products. For more detailed information, please refer to our "Cleaning recommendation Decorative Pfleiderer products".

- For further information, please follow the recommendation in the "Cleaning HPL" leaflet on the site www.icdli.com.

Disposal

- We recommend material or energy recovery in approved plants.

Would you like to learn more?

Please get in touch with us! We look forward to hearing from you.